HATO procures a variety types of working tools

in a broad range of industries

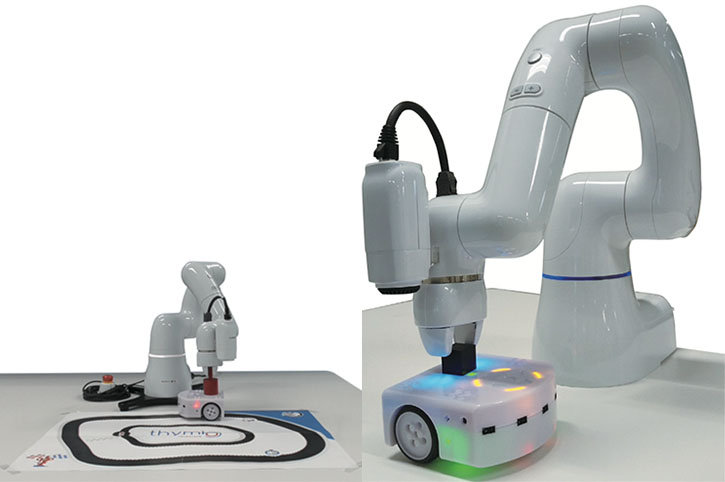

- Machine tools and working machine

- Chemical machines, laboratory tools and the materials

- Building equipment and building materials

- Electric machinery, fiber products, 3D map

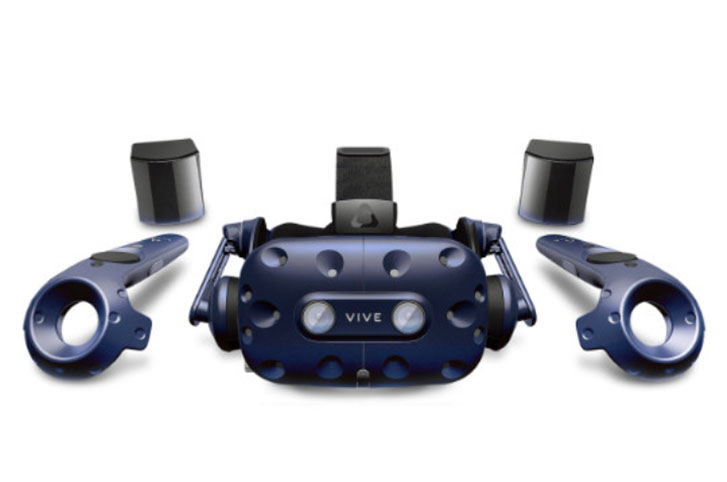

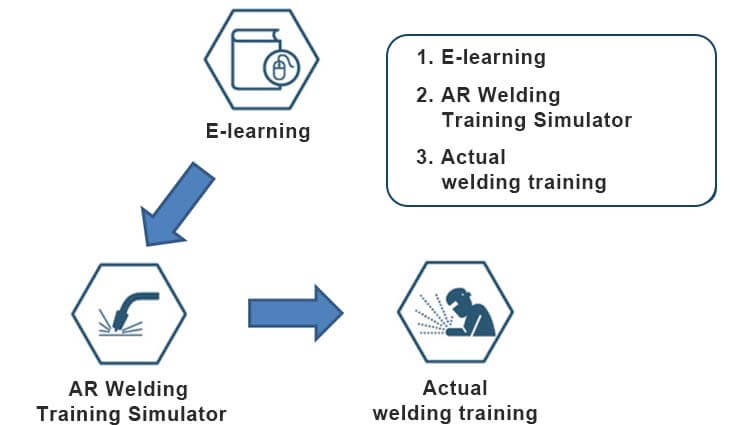

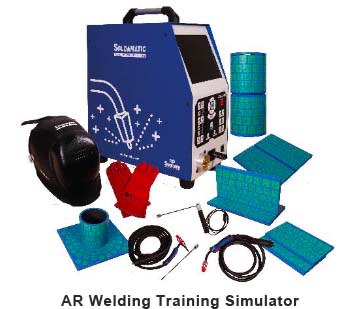

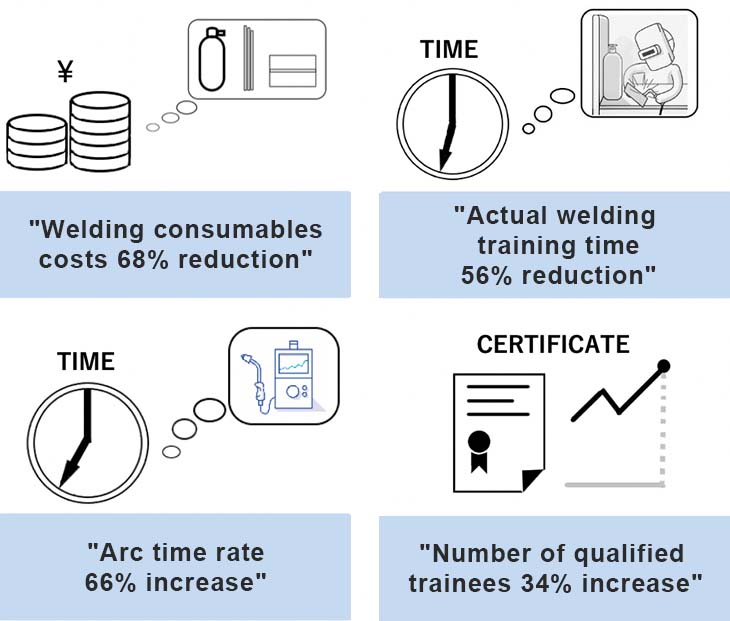

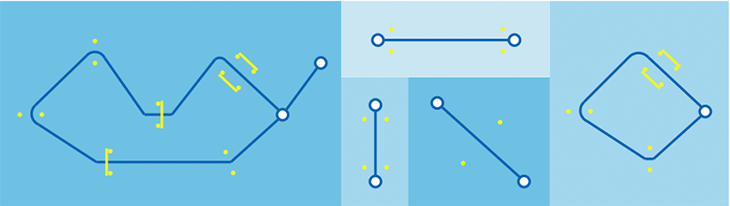

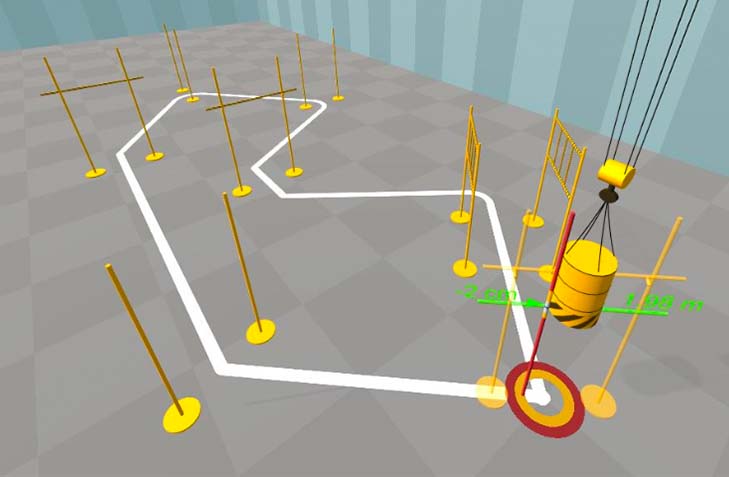

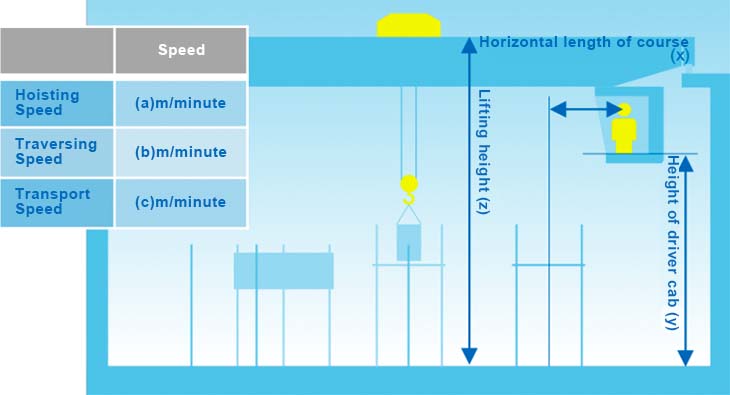

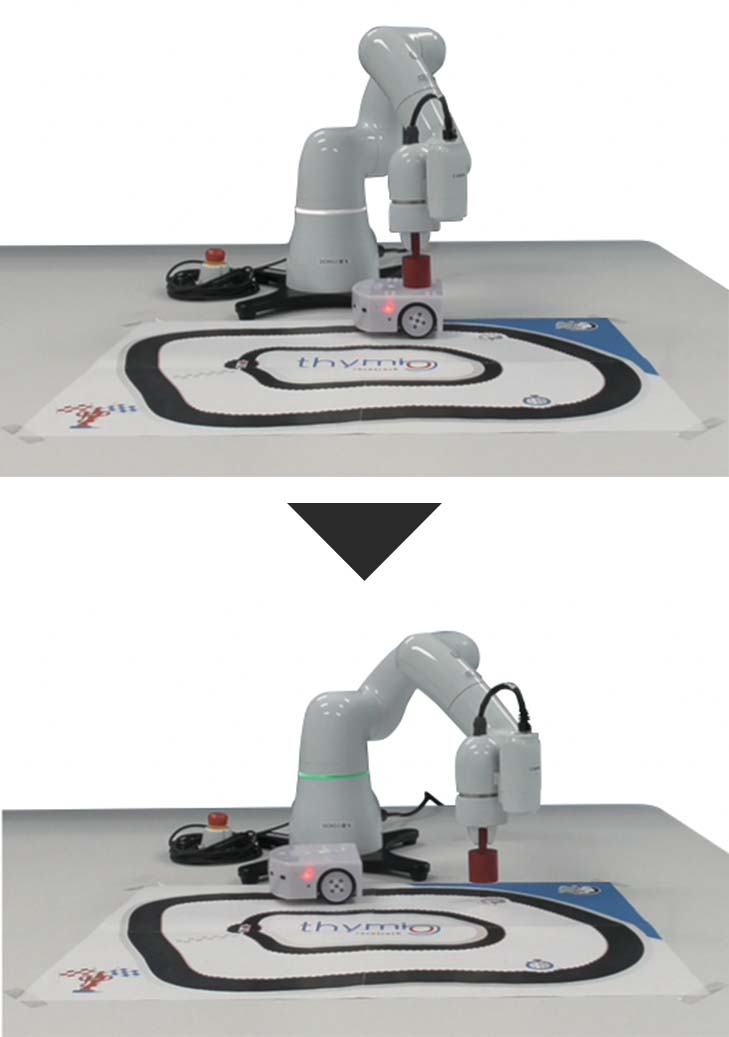

- Training machine tools and software

- Paper converting and commodities

- Designing, production, sales and repairment of industrial machinery

- Construction machinery, cargo-handling machinery and equipment